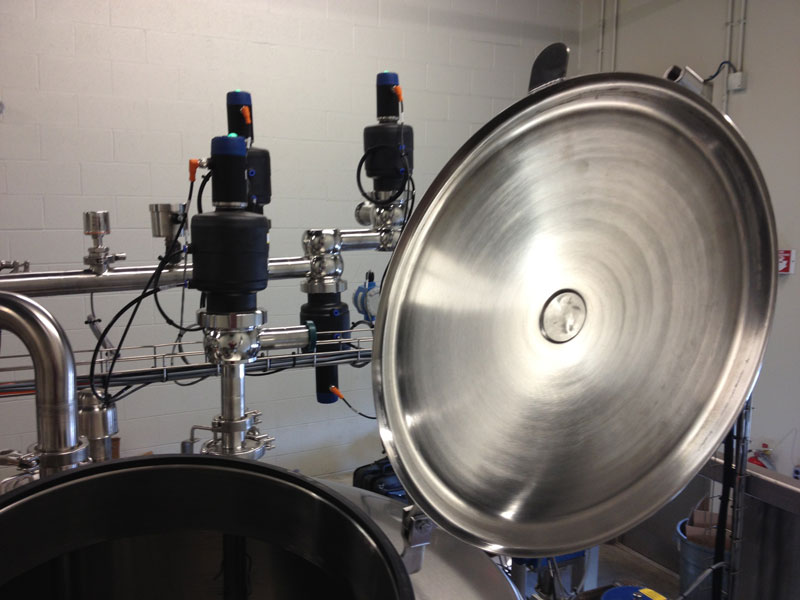

Liquid Processing

In-Tank Solutions

Agitator Types

Skidded Mixing and Blending Systems

Learn More About What We Can Do For You

Request additional information, literature, or speak to us with any questions you may have.