Material Handling

Dumpers

- Dumper carriage and structural frame are fabricated from stainless steel. Lifting carriage is fabricated from 3/8†plate. Bead blasted surface finish.

- Baseline capacity of 3,000-lb., with standard pivot heights of 42″, 54″, 60″ and 70″. Custom configurations and capacities are available.

- Includes 5 hp hydraulic power unit with stainless steel reservoir. Electric components are NEMA 4X rated and suitable for wash down service.

- Safety features ensure dumper remains elevated in the event of a power failure.

- Customized for your container and portability needs.

Screw Conveyors

- Fully customized to meet your specific needs.

- Trough design, with auger diameters up to 30″. Single or dual augers are available.

- Large capacity or small capacity hoppers, depending on throughput needs.

- All stainless steel construction, with an internal surface finish of 32 microinch Ra or better. Exterior surfaces are bead blasted.

- Hydraulic or electric gear motor, with either direct or chain drive.

- Integrated or standalone controls

- Options for heat transfer, pivoting, and angle elevation.

Belt Conveyors

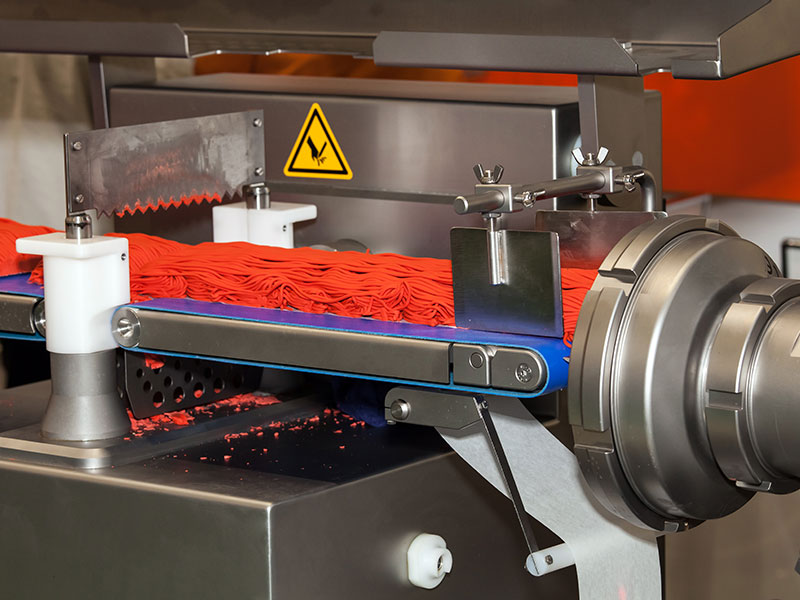

Grinders

- Suitable for fresh or frozen products

- Stainless steel construction with self-feeding hopper

- Hopper capacity from 30 cubic feet to 120 cubic feet

- Capacities up to 60,000 pounds per hour

- Spiral fluted grinding head with ceramic coupling to prevent heat transfer from the motor

- Optionally maintains constant product temperature

Mixer/Blenders

- All stainless steel construction, with the product tub fabricated from plate.

- Capacities between 100 lbs to 15,000 lbs.

- Hydraulically operated lid with integrated power unit. Reservoir is stainless steel.

- Electric or hydraulic drives, with all electronics and control suitable for wash-down service.

- Retractable shaft seals for ease of cleaning. Clean-In-Place (CIP) is available for all units.

- Manual push button control, with start/stop, speed control, jog mode, forward/reverse. Controls are mounted in a NEMA 4X enclosure.

- Paddle mixers for use with shear sensitive products or granular products, while ribbon mixers for use with powders and pastes.

- Optional load cells, steam, CO2 or N2 injection, heat transfer and vacuum to 28 inHg

Learn More About What We Can Do For You

Request additional information, literature, or speak to us with any questions you may have.